Hydrogenation of vegetable oil refers to conversion of unsaturated liquid oil into saturated or partially saturated plastic fat by catalytic addition of hydrogen. Most widely used catalyst is nickel. The main purpose of hydrogenation of vegetable oil is

- To modify oil for application in wide range of food uses such as production of margarine, deep frying oil, shortening in biscuit etc.

- To extend shelf life of fat by improving oxidative stability by reducing unsaturation. Unsaturated fats and oils are very susceptible to spoilage called rancidity.

For successful hydrogenation, crude oil impurities like phosphorous and sulfur compounds, free fatty acids, and residual soap need to be removed before proceeding for hydrogenation. These impurities have poisoning effect on catalyst and reduce its activity. Canola and rapeseed oil are particularly notorious for high level of natural sulfur which can cause problem in hydrogenation.

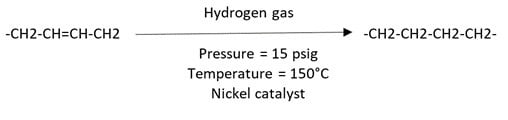

Principle of hydrogenation: Hydrogenation involves reaction among components in different phases. The catalyst is in solid phase, oil in liquid phase and hydrogen in gaseous phase. When unsaturated fatty acid is subjected to high temperature (15 psig) in the presence of hydrogen gas and nickel catalyst, saturated fatty acid is produced. For hydrogenation, liquid oil, solid catalyst and gaseous hydrogen must be brought together at suitable temperature. Hydrogenation is a mass transfer process and thus mass transfer of reactant is a rate limiting factor. Hydrogen is first dispersed as bubbles, then it must dissolve in bulk oil, diffuse to catalyst particle and its surface. Catalyst (Nickel) absorbs significant amount of hydrogen and the absorbed hydrogen is delivered to unsaturated part of fatty acid. For this, triglycerides must also diffuse to catalyst surface to receive to receive hydrogen.

For hydrogenation, liquid oil, solid catalyst and gaseous hydrogen must be brought together at suitable temperature. Hydrogenation is a mass transfer process and thus mass transfer of reactant is a rate limiting factor. Hydrogen is first dispersed as bubbles, then it must dissolve in bulk oil, diffuse to catalyst particle and its surface. Catalyst (Nickel) absorbs significant amount of hydrogen and the absorbed hydrogen is delivered to unsaturated part of fatty acid. For this, triglycerides must also diffuse to catalyst surface to receive to receive hydrogen.

Therefore, higher rate of reaction is achieved raising the temperature and increasing agitation to disperse the gas bubbles. Agitation also keeps the film thickness small. Increasing gas flow rate dissolve hydrogen at high levels. The reaction is carried out in pressurized reactions which creates driving force for dissolution. Other factor influencing the reaction are quantity and activity of the catalyst.

Hydrogenation process: The reaction is normally conducted at 250°C – 300°C for 40 to 60 minutes. The catalyst is mixed to small part of oil at room temperature. The bulk of the oil is pumped into the reactor and vacuum is established by deaerating the oil and oil is heated. Finally oil catalyst slurry (premix) is added. The extent of reaction is followed by monitoring the refractive index (RI) of the oil which is directly related to iodine value. Hydrogenation process: The reaction is normally conducted at 250°C – 300°C for 40 to 60 minutes. The catalyst is mixed to small part of oil at room temperature. The bulk of the oil is pumped into the reactor and vacuum is established by deaerating the oil and oil is heated. Finally oil catalyst slurry (premix) is added. The extent of reaction is followed by monitoring the refractive index (RI) of the oil which is directly related to iodine value.

Hydrogenation process: The reaction is normally conducted at 250°C – 300°C for 40 to 60 minutes. The catalyst is mixed to small part of oil at room temperature. The bulk of the oil is pumped into the reactor and vacuum is established by deaerating the oil and oil is heated. Finally oil catalyst slurry (premix) is added. The extent of reaction is followed by monitoring the refractive index (RI) of the oil which is directly related to iodine value.

Role of catalyst: A catalyst increases the rate of reaction without being lost. Small amount of catalyst are effective in case of hydrogenation. The usual amount is 0.01 to 0.02 % of the weight of oil. Reduced nickel is the most widely used catalyst by vegetable oil industries but copper, platinum, palladium and ruthenium are also effective. Nickel is the catalyst of choice because of good activity, selectivity, filterability and is economic. Since catalytic activity is a surface phenomenon, inducing pore formation increases surface area and thus activity. Pores must be at least 10 nm in diameter in order to accommodate the transfer of triglycerides into them.

Catalyst promoters: catalyst promoters are the substances that enhance the activity of catalyst without having catalyst activity themselves. These substances permit large number of active sites on the catalyst particle. Siliceous materials, aluminum oxide, chromium oxide, cobalt oxide and copper oxide are commonly used catalyst promoters.

Selectivity ratio: selectivity refers to the relative rates of hydrogenation of specific fatty acids. Selective hydrogenation is the opposite of random hydrogenation. Ideally, the most unsaturated fatty acids are hydrogenated before the less unsaturated fatty acids. High selectivity gives high oxidative stability for given iodine value.

About Author

Name : Pratiksha Shrestha

pratiksha.shrestha2001@gmail.com

Ms. Shrestha holds masters degree in food engineering and bioprocess technology from Asian Institute of Technology (AIT) Thailand. She is currently working for Government of Nepal at Department of Food Technology and Quality Control (DFTQC), Kathmandu. She is also a teaching faculty in College of Applied food and Dairy Technology (CAFODAT) affiliated to Purbanchal university, Nepal.