Expansion devises are used in between evaporator and condenser in refrigeration system. These devices meters and regulates the flow of liquid refrigerant to an evaporator. The expansion device have following specific functions.

1. To reduce the pressure of liquid refrigerant coming from condenser.

2. To maintain desired pressure difference between high pressure and low pressure side of the system.

3. Capacity expansion devices are used to maintain the desired rate of flow and pressure drop across the system.

4. To control the flow of refrigerant according to variation of load on the evaporator. Types of expansion devices:

1. Hand operated valve

2. Low side float

3. High side float

4. Capillary tube

5. Solenoid valve

6. Automatic expansion valve

7. Thermostatic valve

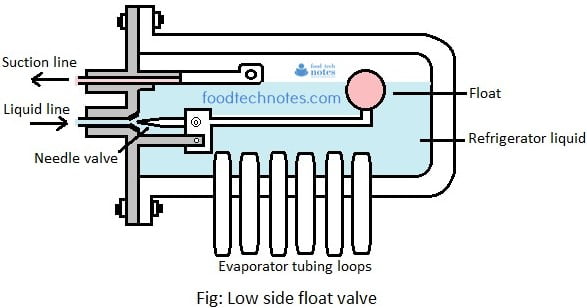

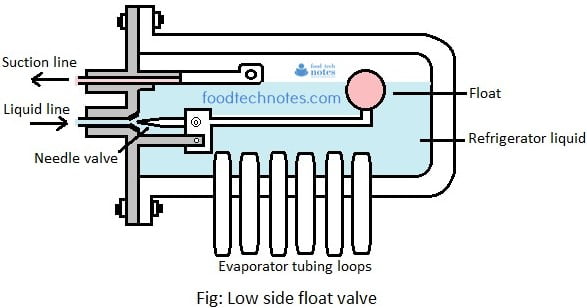

Hand operated valve: These are the simplest expansion device where flow of fluid (refrigerant) us controlled manually. With few exceptions, the manual or hand operated valves are obsolete and are not applied to modern systems. Low side float: A liquid-refrigerant control of the low side float types consists of ball type float located in either a chamber or evaporator itself on the low- temperature side of the system and controlling needle valve through simple lever mechanism. This method of control is restricted to a flooded system and operates to maintain constant level of ebullient refrigerant in the evaporator.

Low side float: A liquid-refrigerant control of the low side float types consists of ball type float located in either a chamber or evaporator itself on the low- temperature side of the system and controlling needle valve through simple lever mechanism. This method of control is restricted to a flooded system and operates to maintain constant level of ebullient refrigerant in the evaporator.

High side float: The only difference between high side and low side float valve is that, the float itself is located in a liquid receiver or an auxiliary liquid container on the high pressure side of the system. This type of valve have disadvantage that evaporator must be placed directly adjacent to the float chamber containing the supply of high pressure and high temperature liquid refrigerant. The relatively higher temperature differences is due to comparatively rapid transfer of heat from this reservoir to evaporating refrigerant with an accompanying loss of available refrigerating effect.

High side float: The only difference between high side and low side float valve is that, the float itself is located in a liquid receiver or an auxiliary liquid container on the high pressure side of the system. This type of valve have disadvantage that evaporator must be placed directly adjacent to the float chamber containing the supply of high pressure and high temperature liquid refrigerant. The relatively higher temperature differences is due to comparatively rapid transfer of heat from this reservoir to evaporating refrigerant with an accompanying loss of available refrigerating effect. Capillary tube: A capillary tube when used as liquid refrigerant expanding device, usually consist of an extremely small bore tube (0.031 – 0.054 inch diameter and 5 – 20 feet long. Its extreme simplicity and low initial cost are compelling reasons for its use. The sizing of capillary tube is essentially a compromise if varying load condition and varying condenser and evaporator temperatures are to be encountered. This is reflected in some increase in average operating cost. Care must be taken to prevent plugging of the tube by any dirt, ice or decomposition products. In general, the flow rate through a capillary tube increases as the tube bore increases and as the bubble point temperature increases.

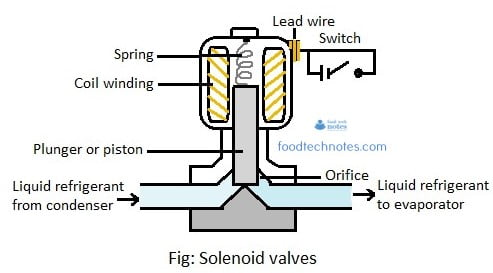

Capillary tube: A capillary tube when used as liquid refrigerant expanding device, usually consist of an extremely small bore tube (0.031 – 0.054 inch diameter and 5 – 20 feet long. Its extreme simplicity and low initial cost are compelling reasons for its use. The sizing of capillary tube is essentially a compromise if varying load condition and varying condenser and evaporator temperatures are to be encountered. This is reflected in some increase in average operating cost. Care must be taken to prevent plugging of the tube by any dirt, ice or decomposition products. In general, the flow rate through a capillary tube increases as the tube bore increases and as the bubble point temperature increases. Solenoid or magnetic stop valves: Solenoid valves are frequently used as liquid stop valves and are placed in liquid line between the condenser or receiver and evaporator. If the solenoid coil is not energized (switched), the plunger and the needle close to the orifice prevents the flow. When solenoid coil is energized, the plunger is drawn into the solenoid, thus opening the solenoid passage.

Solenoid or magnetic stop valves: Solenoid valves are frequently used as liquid stop valves and are placed in liquid line between the condenser or receiver and evaporator. If the solenoid coil is not energized (switched), the plunger and the needle close to the orifice prevents the flow. When solenoid coil is energized, the plunger is drawn into the solenoid, thus opening the solenoid passage.

Magnetic stop valves are widely used for the control of refrigerant flow to individual evaporators in a multiple evaporator system operated by one compressor. Solenoid or magnetic valves has two positions only (fully closed or fully opened). Since, these control devices have fixed area when opened, these devices cannot be used to modulate control of the flow. Automatic expansion device: This is also called AXV of constant pressure expansion valve. As the liquid refrigerant enters from the strainer into the expansion device, the liquid refrigerant is throttled through the orifice with opening size controlled by needle screw and is discharged into the evaporator. The valve is connected to the diaphragm, which expands or contracts with variation in the evaporator pressure. This type of expansion valve is supplied to dry evaporators of direct expansion type. The problem with such expansion device is that,

Automatic expansion device: This is also called AXV of constant pressure expansion valve. As the liquid refrigerant enters from the strainer into the expansion device, the liquid refrigerant is throttled through the orifice with opening size controlled by needle screw and is discharged into the evaporator. The valve is connected to the diaphragm, which expands or contracts with variation in the evaporator pressure. This type of expansion valve is supplied to dry evaporators of direct expansion type. The problem with such expansion device is that,

- When the evaporator load increases than set condition, evaporator pressure increases, thus pushing the diaphragm upward and closing the valve and restricting the flow of refrigerant to evaporator. But in actual, when load increases, there should be more supply of refrigerant. This condition is called starvation of refrigerant.

- When evaporator load decrease than set condition, evaporator pressure decreases. Thus spring pressure will push the diaphragm below and opening the valve and let refrigerant flow into the evaporator. But in actual, when load decreases, less refrigerant is required. This condition is called over flooding of refrigerant.

Thermostatic expansion valve: A thermostatic expansion valve controls the flow of liquid refrigerant to the evaporator in such a way so as to keep practically the entire coil filled with evaporating refrigerant vapor leaving the coil. TXV is similar to AXV in construction, with only difference of addition of power element in TXV. The power element consists of bellows, capillary tube and feeler bulb. The feeler bulb measures the temperature of refrigerant at the outlet of evaporator tube and as the feeler bulb temperature increases, bulb pressure also increases, which push the diaphragm downward, opening the valve and letting the refrigerant flow into the evaporator to carry away (draw) more heat from the evaporator. When the bulb temperature decreases, bulb pressure also decreases, cooling the valve and thereby restricting the flow of refrigerant into evaporator. Thus thermoplastic expansion valve is most desirable in comparison to automatic expansion valve. TXY gives remedy to starved condition and over-flooding of evaporator.

Thermostatic expansion valve: A thermostatic expansion valve controls the flow of liquid refrigerant to the evaporator in such a way so as to keep practically the entire coil filled with evaporating refrigerant vapor leaving the coil. TXV is similar to AXV in construction, with only difference of addition of power element in TXV. The power element consists of bellows, capillary tube and feeler bulb. The feeler bulb measures the temperature of refrigerant at the outlet of evaporator tube and as the feeler bulb temperature increases, bulb pressure also increases, which push the diaphragm downward, opening the valve and letting the refrigerant flow into the evaporator to carry away (draw) more heat from the evaporator. When the bulb temperature decreases, bulb pressure also decreases, cooling the valve and thereby restricting the flow of refrigerant into evaporator. Thus thermoplastic expansion valve is most desirable in comparison to automatic expansion valve. TXY gives remedy to starved condition and over-flooding of evaporator. Useful links:

Useful links:

How Thermostatic valve works?

How Solenoid valve works?

About Author

Name : Pratiksha Shrestha

pratiksha.shrestha2001@gmail.com

Ms. Shrestha holds masters degree in food engineering and bioprocess technology from Asian Institute of Technology (AIT) Thailand. She is currently working for Government of Nepal at Department of Food Technology and Quality Control (DFTQC), Kathmandu. She is also a teaching faculty in College of Applied food and Dairy Technology (CAFODAT) affiliated to Purbanchal university, Nepal.