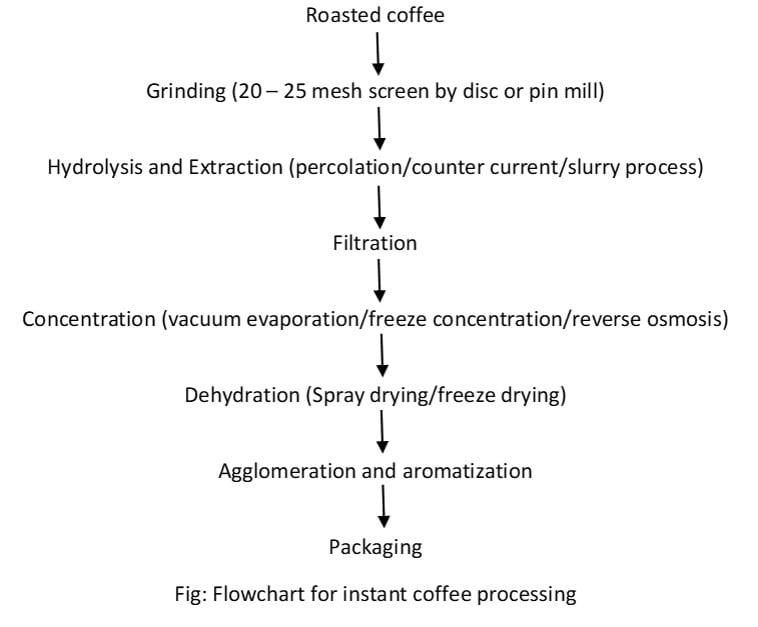

Instant coffee is also called soluble coffee or coffee powder. It is a beverage derived from brewed coffee beans. The major goal is to produce an instant coffee that taste as better as freshly brewed coffee. Modern technology uses methods that does not require addition of carbohydrate component during production. The process includes following steps. Hydrolysis and extraction: Manufacturing instant coffee begins with brewing grounded coffee powder in highly efficient extraction equipment. Soft water is processed through series of 5 – 8 column of ground coffee beans. The water is placed through several hot cells (140 – 180°C) which operate at higher atmospheric pressure for extraction of difficult component like carbohydrate. It is then passed through heat exchanger to cool it to about 5°C. At the end of this cycle, coffee extract contains 20 – 23 % solid.

Filtration and concentration: After filtering the brewed coffee, it is treated in several ways to improve its concentration. The goal is to create an extract containing about 40 % solid. In some cases, the liquid is processed in a centrifuge to separate out the lighter water from heavy coffee. Another technique is to remove water by evaporation before cooling the hot brewed extract. The third alternative is to cool the extract enough to freeze water. Then ice crystal is mechanically separated from coffee concentrate.

Dehydration: Two basic methods are available for the conversion of liquid coffee extract to dry form. They are spray drying and freeze drying. Spray drying is done at high temperature which affects the taste of final product but it is less costly than free drying.

1. Spray drying: Cool and clarified liquid concentrate is sprayed through a nozzle at the top of drying tower. The tower is at least 75 ft. tall. Air that has been heated to about 250°C is blown downward through the mist to evaporate the water. The air is diverted out of tower near the bottom and it is filtered to remove fine particles which can be recirculated back through the tower during the agglomeration step. The dry coffee powder is collected in bottom of the tower before being discharged for further processing. The powder contains about 2- 4 % moisture and consists of free flowing non-dusted particle. Spray drying may be followed by a step (agglomeration) to form the powder into coarser particles that will dissolve more completely. The agglomeration process basically involves rewetting the surface of coffee powder particles and bringing the particles into contact so they will adhere to each other and form larger and more granular particle.

2. Freeze drying: It may be used instead of spray drying. This process begins with primary freezing. By this, coffee extract is chilled to slushy consistency at about -6° The pre-chilled slush is placed on a steel belt and further cooled in a series of steps until temperature reaches to – 40 to – 45°C. Quick cooling process (30 second to 2 minutes) result in smaller, lighter color products while the slower process (10 minutes to 180 minutes) generate larger and darker granules. After that, frozen slabs are broken into pieces and grounded into particles of proper size for drying purpose. The particles are sieved to ensure proper sizing and those that are too small are melted and returned to primary freezing stage. The frozen particles are sent to drying chamber.

Aromatization: Aromatic volatiles that have been recovered from earlier step in the manufacturing instant coffee by spray drying process are sprayed back on dried coffee particles. The enjoyment of making and drinking coffee is the pleasant aroma of coffee itself. During several step of manufacturing process, volatile aroma elements are lost. By the process of aromatization, lost volatiles are put back into the coffee powder. It involves two steps

1. Recovery of flavoring fraction and its concentration or purification

2. Re- incorporation of these aroma fraction into instant coffee powder

Aroma is recovered mainly by two methods

1. Head space gas recovery system: In this system, the coffee grinding is done in closed condition where the inert gas is flushed after grinding and aroma are stripped. The aroma loaded inert gas is then subjected to low temperature where aroma compound are recovered as frozen mass.

2. Extract stripping system: In this system, aroma is recovered during the percolation stage just before extraction. The grounded coffee is subjected with steam and the steam carries aroma component from the mass. These aroma steam mixture is condensed and aroma fraction is separated, purified and concentrated.

The recovered aroma can be added to instant coffee in various ways. The most commonly used aroma incorporation system in coffee are as follows

1. Aroma loaded gas is passed over the instant coffee which is placed in the fixed bed as a result the coffee absorbs the aroma whereas gas is released out.

2. The aroma fraction is mixed with coffee oil and is sprayed to instant coffee

3. The aroma is encapsulated in sodium alginate, gelatin, soluble starch and mixed back to instant coffee.

4. Instant coffee is placed together with roasted coffee for some time. The instant coffee takes the flavoring compound from roasted bean.

Agglomeration: it is also called instantizing process where the fine particle of coffee are assembled together to make them granular in size. The product obtained from spray drier is of very fine particle size which makes them to float in water making dispersion rather than making instant solution. Hence, these small particle should be fused together to produce more dense product which readily sinks in water and dissolves.

The main objective of agglomeration is to enhance the better solubility of the particles. It also improve the color of coffee which becomes darker after agglomeration. The fusion of smaller particle also make the particle stronger which do not break during subsequent handling and transportation.

The main objective of agglomeration is to enhance the better solubility of the particles. It also improve the color of coffee which becomes darker after agglomeration. The fusion of smaller particle also make the particle stronger which do not break during subsequent handling and transportation.

The agglomeration takes place in a roasting drum. In this drum, the coffee particles get wet and sticky as a result they form larger granule size which are again dried and cooled in fluidized bed drier. After sieving, the final product is collected in air proof bags.

Packaging: Instant coffee particle are highly hygroscopic in nature. They absorb moisture from air and environment. Therefore, they must be packed under a low humidity condition in a moisture proof container to keep the product dry. Also to prevent loss of aroma and flavor. The product is packaged in low oxygen atmosphere (usually CO2 or nitrogen) and the packaging which have low GTR and WVTR. The best and most widely used packaging for instant coffee is glass jar, laminates and sachets made from laminates.

Useful link:

How instant coffee is made in industry?

About Author

Name : Pratiksha Shrestha

pratiksha.shrestha2001@gmail.com

Ms. Shrestha holds masters degree in food engineering and bioprocess technology from Asian Institute of Technology (AIT) Thailand. She is currently working for Government of Nepal at Department of Food Technology and Quality Control (DFTQC), Kathmandu. She is also a teaching faculty in College of Applied food and Dairy Technology (CAFODAT) affiliated to Purbanchal university, Nepal.